The present-day business scenario is highly competitive and volatile. Most of the time business managers have numerous plans to execute and multiple strategies to implement. While plans are made rather spontaneously, the time taken to turn them into fruitful action turns out to be quite long. And this problem arises from the absence of what…

Month: November 2017

Print Management Solutions Advantages by Samer El Bizri

Nowadays by utilizing the application of print management solutions, it is feasible for firms to manage jobs of printing, print quotes and logs and auditing the print. It might be imperative in few cases for the individual printing any particular documents or document to enter a pin number and the user name since print documents…

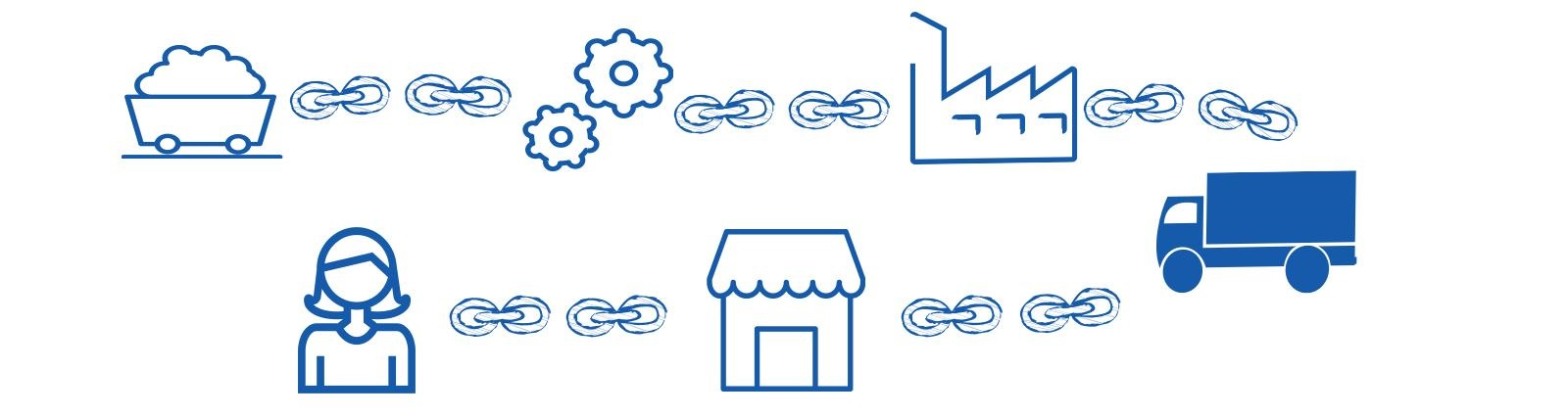

Why Supply Chain Management System?

Improvised supply chain gives a business competitive advantage in the market and it helps the business to mitigate risks related with acquiring raw materials and offering pinpointed products and/or services. By properly implementing supply chain management systems, a business can effectively streamline its operational objectives, reduce waste, overhead costs and tackle the challenging issue of…

Supply Chain Management: Focal Factors To Consider and Integrate

In the backdrop of global economic sluggishness, fluctuating fuel prices, increasing concerns over safety and subsequent social regulations, escalating expectations of clients, effects of globalization, streamlined technology, ever-changing transportation scenario, rising transportation costs, and declining capacity, shipping industry is exasperated managing their impacts. Managers handling freight shipping services nationally and internationally are faced with an…

Optimize The Speed of Your Business With SCM Software Solution

Companies that are preparing to implement logistics and supply chain management software solutions for the first time may be a little curious about how these types of software tools help business operations. However, CIOs and the others in leadership often understand the rush towards supply chain management (SCM) and other types of enterprise planning tools.…

Optimizing Supply Chain Management in Small and Medium Scale Enterprises

We have vast numbers of Small and Medium Enterprises (SME) in any given economy but their impact in national economic development is relatively low due to low operational efficiency. Implementation of Supply Chain Management system in SME will reduce operational cost and increase efficiency. Implementing an effective Supply Chain Management system in SME has…

Optimizing Supply Chain Can Deliver Value – Samer El Bizri

Supply chain departments typically control the flow of goods/materials from suppliers to customers. An organizations supply chain function can consume a significant portion of business costs, through their control of a large percentage of the cost of sale. Inefficient supply chains can be characterized by bureaucracy and ‘hidden costs’ or waste such as overstocking inventory,…

Hello world!

Welcome to BCZ. This is your first post. Edit or delete it, then start blogging!